Among the 30s and 50s Daniele Gasperini developed different models of the thermodynamic engine at low temperature. They were different in size and performance, but always made mainly cast iron and based on a mechanism “connecting rod – crank”. In Nova Somor our Roberto Belardinelli, in addition to using more modern materials characterized by greater resistance, reliability and lightness compared to cast iron, he used a piston mechanism aligned on the same axis that reduces to the maximum the energy losses due precisely to the “connecting rod – crank “. The result was an invention whose patent was filed in early 2015.

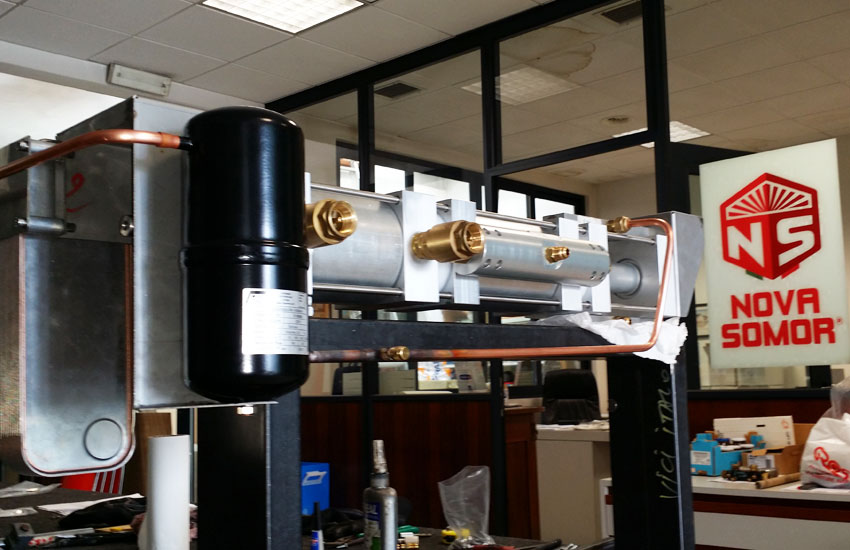

During the winter of 2014-2015 we got to experience long-mechanics of our thermodynamic engine, the cylinder of the gas supply and the hydraulic pump being able to achieve excellent results. Having designed and built each component, they have been assembled in our workshop several complete groups which have spent hundreds of hours on the test bench. Kettle replaced the heat of the summer sun and a chiller simulated the fresh water of a well. First we switched valves piston movement of the motor, which is positioned inside the central cylinder of the assembly, consisting of three cylinders mounted on the same axis. Then he worked extensively on seals and their compatibility with the volatile gas used to create the thermodynamic cycle of the engine.

So then we worked on the calibration of the feed cylinder of liquefied gas, to detect the correct displacement in relation to that of the engine cylinder and to the evaporator. Then it was developed the hydraulic pump and finally we worked on the reduction and / or elimination of all friction and the final choice of the materials used and surface treatments to do. The result is balanced, powerful and reliable. Some problems of “teething” it can still give, as all new systems of recent invention do, but they will certainly be problems manageable and above “normal” in statistical terms.

As shown in our recent short video after one year since the founding of Nova Somor, we are ready for the market. Having started as innovative start-up in mid-July 2014, we arrived at the first prototype machine complete in late September. For this reason, last year we had a only few days of autumn sunshine to test the solar collector. The data we have been collecting have been promising, but we did not have the time needed as it was for the system pump – motor.

Fortunately the last 60 days between mid-May and today were full of sunny days that we could use to develop the solar collectors. But as for the engine system – pump there were never doubts, with the solar collector we were to evaluate two very different technologies: that of the roll bond and that of the finned pack. Both are appropriate, but they have different strengths and different defects that must be seen and experienced on the field. These tests made us very busy and committed our energies for much longer than we expected: we have at least a couple of months behind schedule that we set in 2014. In these days we are completing the tests for the first deliveries of complete NS1 in Italy and in Africa.

ITA

ITA ENG

ENG FRA

FRA ESP

ESP POR

POR